Unmanned Weighbridges

Experience futuristic weighing machines with our automated systems. Enjoy seamless, operator-free weighing with real-time data integration and precision like never before. Boost your productivity effortlessly!

Unmanned Weighbridges Systems

Precision at Your Fingertips: Weighing Made Effortless

Imagine a world where truck weighing is efficient and free from the constraints of human oversight. Introducing our Unmanned Weighbridge System (UWS), a groundbreaking automation solution that is revolutionising the weighing process.

Our weighbridges, developed in Chennai, are meticulously designed to enhance operational efficiency with unparalleled accuracy. By incorporating advanced peripheral devices, our unmanned weighbridge and intelligent control systems streamline time-consuming, labour-intensive tasks for applications across industries.

Experience the future of weighing with Giri Brothers’ Unmanned Weighbridges, where reliability meets futuristic requirements tailored to your business. Every weigh-in is a step towards improved productivity. Discover how our innovative technology and design can transform your operations.

Smart Business Solutions for Unmanned Weighbridge Management

Cloud Software for Real-Time Monitoring

Digital Records for Transparency

Reliable Receipts for Assurance

Remote Access Anytime, Anywhere

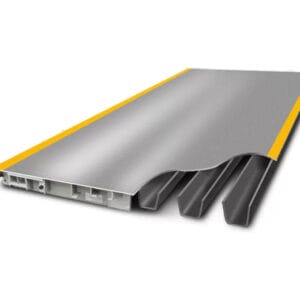

Product Specification

Specification | Detail |

Model | DW |

Make | CIBI |

Weigh Bridge Type | Digital, Unmanned Weigh Bridges |

Weighing Capacity | 30 t–150 t |

Standard Platform Sizes | 7.5x3 m, 9x3 m, 12x3 m,16x3 m, 18x3 m |

Customised Platform Size | Tailored designs available for off-road weighbridges |

Weight Terminal | Microcontroller-based intelligent terminal |

Power Source | 90 V–270 V AC @ 50 Hz/60 Hz |

Display | LED weight display and 16x2 backlit LCD for parameter display. Includes jumbo display for enhanced visibility |

Input | IBM AT-type keyboard |

Output Interface | RS-232C for computer or printer interface |

Printer Interface | Directly connects to a printer for comprehensive printouts |

Operating Temperature | 10℃–55℃ |

Reports | Date-wise, RST-wise, and all five entries-wise reporting options |

Measurement Type | Double-ended shear beam load cells, analogue or digital |

Software Option | Choose from standard software or customise it to your needs |

Our Unmanned Weighbridges: Features

- Advanced mounting blocks for sturdy and heavy-duty reliability.

- Seamless compatibility with PCs, laptops, printers, and keyboards.

- Dual-display indicator for easy setting and accurate reading.

- IP68-rated steel load cells for accuracy and long-term durability.

- Customisable weight-processing software.

- Weatherproof junction box to protect against electricity surges.

- Automated printouts with detailed data.

- One-year warranty covering load cells and indicators.

Simplify Your Workload With Our Automated Weighbridges

Our Unmanned Weighbridges: Benefits

- Round-the-clock operability

- Unmatched accuracy

- Custom-fit solutions

- Automated data management

- Remote monitoring and controlling

- Advanced, user-friendly interface

- Durable and robust construction

- Fast weighing process

somnath –

FOR MINES