bench weighing machine

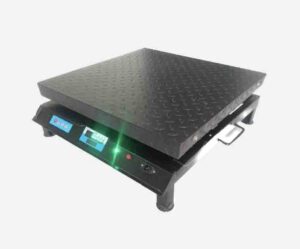

BENCH WEIGHING MACHINE

A bench weighing machine, also known as a bench scale, is a type of weighing equipment designed for use on a bench or tabletop. These scales are versatile and find applications in various industries for weighing smaller loads. Here’s an outline to explore the features and applications of bench weighing machines:

giribrothers.in

product list

1. Introduction to Bench Weighing Machine

- Define the purpose of bench weighing machine.

- Highlight their versatility and common applications in different industries.

2. Compact and Portable Design

- Explore the compact and bench weighing machine space-efficient design of bench weighing machine.

- Discuss how this design makes them suitable for use on benches or tables.

3. Weighing Capacity and Precision

- Detail the scale’s bench weighing machine capacity and precision, emphasizing accuracy in measuring smaller loads.

- Discuss the suitability for various industries and applications.

4. Materials and Construction

- Discuss the materials used in the bench weighing machineconstruction of bench weighing machine.

- Explore how durability is ensured for consistent and reliable performance.

5. Platform Size and Configuration

- Explore different platform sizes and configurations available for bench weighing machine.

- Discuss how these variations cater to diverse weighing needs.

6. Digital Display and Readability

- Highlight the digital display features of bench weighing machine.

- Discuss readability and user-friendly interfaces.

7. Tare Functionality for Net Weight Measurement

- Explain the bench weighing machine tare function and its significance in measuring the net weight of items on the bench.

- Discuss how this feature contributes to efficiency.

8. Units of Measurement

- Discuss the supported units of measurement, catering to different user preferences and industry standards.

- Explore any conversion capabilities.

9. Battery Life and Power Management

- Discuss the power source of bench weighing machine and their suitability for prolonged use.

- Explore battery life and any power-saving features.

10. Connectivity Features

- Explore any connectivity features, such as USB ports or wireless options.

- Discuss how these features facilitate data transfer and integration with other systems.

11. Industries and Applications

- Discuss the wide range of industries and applications where bench weighing machine are commonly used.

- Highlight specific use cases in manufacturing, laboratories, retail, and more.

12. Portability and Easy Maintenance

- Discuss the portability of bench weighing machine.

- Provide insights into maintenance practices for prolonged and reliable use.

13. Safety Features

- Explore any safety features integrated into bench weighing machine.

- Discuss features like overload protection or stability indicators.

14. Cost-Effectiveness and Affordability

- Discuss how bench weighing machine provide a cost-effective weighing solution for smaller loads.

- Explore their affordability compared to larger industrial scales.

15. User Testimonials and Success Stories

- Share testimonials from users who have found success using bench weighing machine.

- Provide insights into the practical benefits and real-world applications.

16. Future Trends in Bench Weighing machine

- Discuss emerging trends and potential future developments in bench weighing machine.

Bench weighing machines find applications across various industries due to their versatility, accuracy, and compact design. Here are some common applications of bench weighing machines:

1. Manufacturing and Production:

- Weighing raw materials and components during the manufacturing process.

- Checking and monitoring the bench weighing machine of finished products before packaging.

2. Laboratories:

- Weighing chemicals bench weighing machine and samples in laboratory settings.

- Ensuring accurate measurements for experiments and research.

3. Retail and Shops:

- Weighing goods bench weighing machine at checkout counters in grocery stores and supermarkets.

- Measuring items for sale in specialty shops, such as delis or bulk food stores.

4. Shipping and Logistics:

- Weighing packages for accurate shipping and logistics operations.

- Checking the weight of items in distribution centers.

5. Food Industry:

- Bench weighing machine ingredients in commercial kitchens and bakeries.

- Ensuring precise measurements for recipes in food processing.

6. Pharmaceuticals:

- Weighing pharmaceutical ingredients and compounds in manufacturing.

- Ensuring accuracy in dosage measurements.

7. Quality Control:

- Verifying the bench weighing machine of products as part of quality control processes.

- Ensuring compliance with weight specifications.

8. Hospitals and Healthcare:

- Weighing bench weighing machine medications for accurate dosages.

- Measuring ingredients for compounding medications.

9. Education:

- Educational institutions for scientific experiments and classroom demonstrations.

- Teaching students about weight and measurement.

Bench weighing machines have diverse applications across various industries due to their precision and versatility. Some common applications include:

- Manufacturing: Bench weighing machines are used for accurate measurement of raw materials, components, and finished products in manufacturing processes, ensuring quality control and consistency.

- Laboratories: In scientific and research laboratories, bench weighing machines are essential for precise measurements of chemicals, samples, and substances.

- Pharmaceuticals: Bench weighing is crucial in pharmaceutical production for measuring ingredients accurately during the formulation of medications.

- Food Industry: Bench weighing machines play a vital role in the food industry for portion control, recipe formulation, and quality assurance.

- Retail: In retail settings, these machines are employed for tasks like weighing produce, portioning deli items, and managing inventory efficiently.

- Logistics and Shipping: Bench weighing machines are used to accurately measure and record the weight of packages before shipping, helping in logistics and ensuring compliance with weight regulations.

- Quality Control: These machines aid in quality control processes by providing precise measurements of components and products, ensuring that they meet established standards.

- Chemical Industry: Bench weighing is integral in the chemical industry for measuring and mixing various substances accurately.

- Mining: In mining operations, bench weighing machines are used to measure and monitor extracted materials, facilitating efficient resource management.

- Education: Bench weighing machines are utilized in educational settings, such as classrooms and laboratories, for teaching purposes and conducting experiments that require accurate measurements.

- Healthcare: In healthcare facilities, these machines are used for weighing patients, measuring medical supplies, and ensuring accurate dosages in pharmaceutical preparations.

- Environmental Testing: Bench weighing machines are employed in environmental testing to measure and analyze samples accurately.

- Jewelry Manufacturing: In jewelry making, precision is paramount, and bench weighing machines are used for accurately measuring precious metals and gemstones.

- Plastics Industry: Bench weighing is essential in the plastics industry for measuring and mixing raw materials in precise quantities during the production process.

- Agriculture: Bench weighing machines find applications in agriculture for measuring seeds, fertilizers, and other agricultural inputs.

bench weighing machines that you could explore in more detail:

- Technology Advancements:

- Explore the latest technological features integrated into modern bench weighing machines, such as digital displays, connectivity options, and advanced sensors.

- Accuracy and Precision:

- Delve into the mechanisms and calibration methods employed in bench weighing machines to ensure accurate and precise weight measurements.

- Portability and Compact Design:

- Discuss the portability and compact design of bench weighing machines, making them suitable for various environments and easy to move around.

- Industrial Applications:

- Explore specific industrial applications where bench weighing machines play a crucial role, such as manufacturing, production, and quality control processes.

- Laboratory Use:

- Highlight the use of bench weighing machines in laboratory settings, emphasizing their role in scientific research, experiments, and sample measurements.

- Weighing Capacity Range:

- Discuss the varying weight capacities available in bench weighing machines and how different models cater to specific weighing needs.

- Materials and Construction:

- Examine the materials used in the construction of bench weighing machines, emphasizing durability, corrosion resistance, and suitability for different environments.

- User Interface and Controls:

- Analyze the user interface and control features of bench weighing machines, including touchscreens, keypads, and the ease of operation.

- Connectivity Options:

- Explore the connectivity options offered by bench weighing machines, such as USB, Bluetooth, or Wi-Fi, for data transfer and integration with other systems.

- Legal Compliance:

- Discuss the importance of bench weighing machines complying with legal metrology standards and regulations to ensure fair trade practices.

- Calibration Processes:

- Provide insights into the calibration processes of bench weighing machines, highlighting the importance of regular calibration for accurate results.

- Power Options:

- Examine the power options available for bench weighing machines, including AC power, battery operation, or a combination of both.

- Checkweighing Features:

- Explore the checkweighing functionality of bench weighing machines, allowing users to set weight limits and ensure products meet specific criteria.

- Data Logging and Memory:

- Discuss the data logging capabilities of bench weighing machines, emphasizing the storage of weight data, measurements, and historical records.

- Environmental Considerations:

- Consider the environmental conditions in which bench weighing machines operate, and discuss features that make them suitable for different climates or settings.

- Integration with ERP Systems:

- Explore how bench weighing machines can integrate with Enterprise Resource Planning (ERP) systems for streamlined data flow and efficient management.

- Maintenance Best Practices:

- Provide guidelines on the maintenance and care of bench weighing machines to ensure longevity and consistent performance.

- Cost-Benefit Analysis:

- Conduct a cost-benefit analysis of bench weighing machines, considering factors such as initial investment, maintenance costs, and long-term benefits.

- Customer Reviews and Feedback:

- Summarize customer reviews and feedback related to specific models of bench weighing machines, providing insights into user experiences.

- Emerging Trends:

- Explore emerging trends in bench weighing technology, such as the incorporation of artificial intelligence, IoT connectivity, or industry-specific adaptations.

somnath –

REVIEWS ACROSS WEB

https://www.facebook.com/giribrothers1973/