Trolley Weighing machine

TROLLEY WEIGHING MACHINE

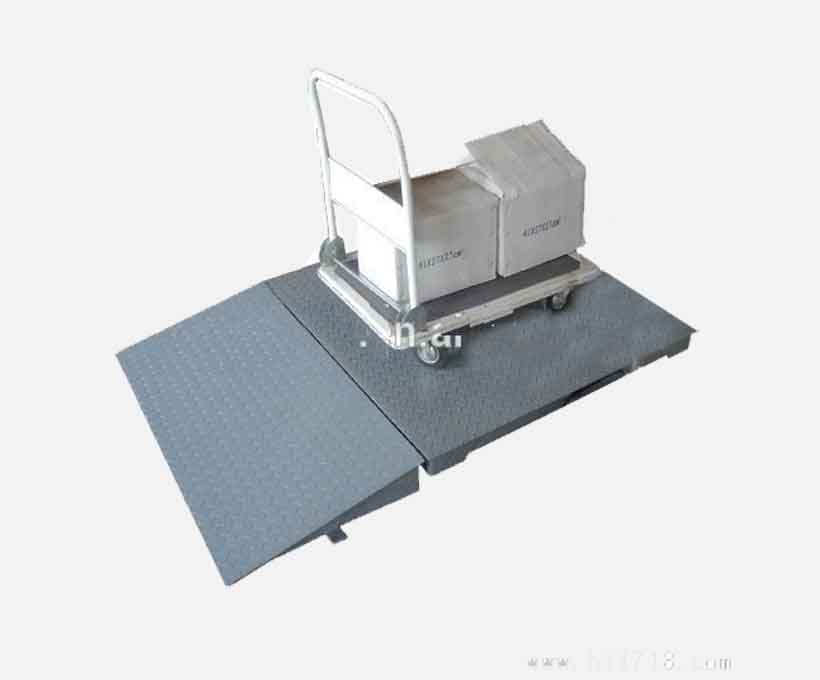

A trolley weighing machine, also known as a trolley scale or mobile weighing system, is a type of weighing equipment designed to weigh objects or materials placed on a trolley or cart. These devices are commonly used in various industries, including manufacturing, logistics, warehouses, and transportation, where there is a need to weigh items on the move.

youtube-giribrothers

features of Trolley weighing machines:giribrothers.in

- Mobility: Trolley weighing machine are designed to be mobile, allowing users to easily move them to different locations within a facility.

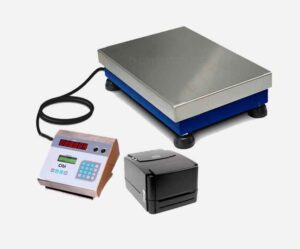

- Accuracy: They are built with precision weighing mechanisms to provide accurate weight measurements.

- Durability: Trolley weighing machine are often constructed with robust materials to withstand the demands of industrial environments.

- User-friendly Interface: They typically come with user-friendly interfaces for easy operation and readability of weight measurements.

- Various Capacities: Trolley weighing machine come in different weight capacities to accommodate a range of loads.

- Battery Power: Some models may be battery-powered for increased flexibility and ease of use, especially in areas where power sources may be limited.

Trolley weighing machines are designed for the purpose of weighing various types of trolleys or carts in different industrial and commercial settings. Here are several applications of trolley weighing machines:

- Material Handling and Logistics:

- Weighing trolleys used for transporting materials within warehouses, distribution centers, and manufacturing facilities.

- Efficiently manages inventory and ensures accurate loading and unloading.

- Retail and Supermarkets:

- Weighing shopping carts in supermarkets for accurate tracking of purchased goods.

- Helps in preventing theft and ensuring correct billing based on the weight of items.

- Airports and Transportation:

- Weighing luggage trolleys at airports to comply with weight restrictions for airport carts or baggage transport.

- Hospitals and Healthcare Facilities:

- Weighing medical supply carts or patient transfer trolleys for accurate medication dosage and inventory control.

- Laundry Services:

- Weighing laundry carts in hotels, hospitals, or commercial laundry services to determine the weight of soiled or clean linens.

- Manufacturing and Production:

- Weighing material transport trolleys to ensure accurate quantities of raw materials are being used in the production process.

- Monitoring the weight of finished goods on trolleys for quality control.

- Food Industry:

- Weighing food service trolleys in catering operations, airlines, or large-scale kitchens.

- Ensuring accurate portion control and compliance with food safety regulations.

- Waste Management:

- Weighing waste collection trolleys for tracking and billing purposes in commercial and municipal waste management.

- Construction Sites:

- Weighing trolleys used for transporting construction materials on-site.

- Monitoring the weight of tools and equipment on utility trolleys.

- Agriculture:

- Weighing agricultural trolleys carrying harvested crops or produce.

- Ensuring accurate measurement for fair trade and distribution.

- Automotive Industry:

- Weighing parts and components on maintenance or production trolleys.

- Ensuring compliance with weight limits during transportation within automotive facilities.

- Event Management:

- Weighing event equipment and supplies on trolleys during setup and breakdown.

- Facilitating accurate logistics planning for events and exhibitions.

- E-commerce Warehousing:

- Weighing order fulfillment trolleys to ensure correct packaging and shipping based on weight.

- Optimizing logistics processes in large-scale e-commerce warehouses.

- Education and Research:

- Weighing laboratory trolleys in educational institutions for accurate measurement of equipment and supplies.

- Ensuring safety and compliance in educational settings.

“Optimizing Operations: Sub-Topics on Trolley Weighing Machine Applications”

- Logistics Precision: Explore how trolley weighing machine streamline logistics processes, ensuring accurate weight measurements for efficient transportation and shipping.

- Warehouse Management: Examine the role of trolley weighing machines in effective warehouse management, providing real-time weight data for inventory control and storage optimization.

- Safety Compliance: Discuss how trolley weighing machine contribute to ensuring compliance with safety regulations, particularly in industries where weight limits are critical for transport and storage.

- Customized Solutions: Highlight the flexibility of trolley weighing systems, showcasing how they can be tailored to specific industry needs, accommodating various trolley sizes and weights.

- Data Integration: Explore the integration of trolley weighing systems with data management software, providing businesses with comprehensive insights for decision-making, process improvement, and overall operational efficiency.

Reviews

There are no reviews yet.